The Flashforge Adventurer 5M is a new-generation 3D printer that promises high-speed printing and user-friendly operation at a budget-friendly price. This long-form review covers every aspect of the Adventurer 5M, from its design and setup to its performance and suitability for various users. Is this CoreXY, auto-leveling machine truly a game-changer for hobbyists, educators, small businesses, and even professionals? Read on to find out.

Design and Build Quality

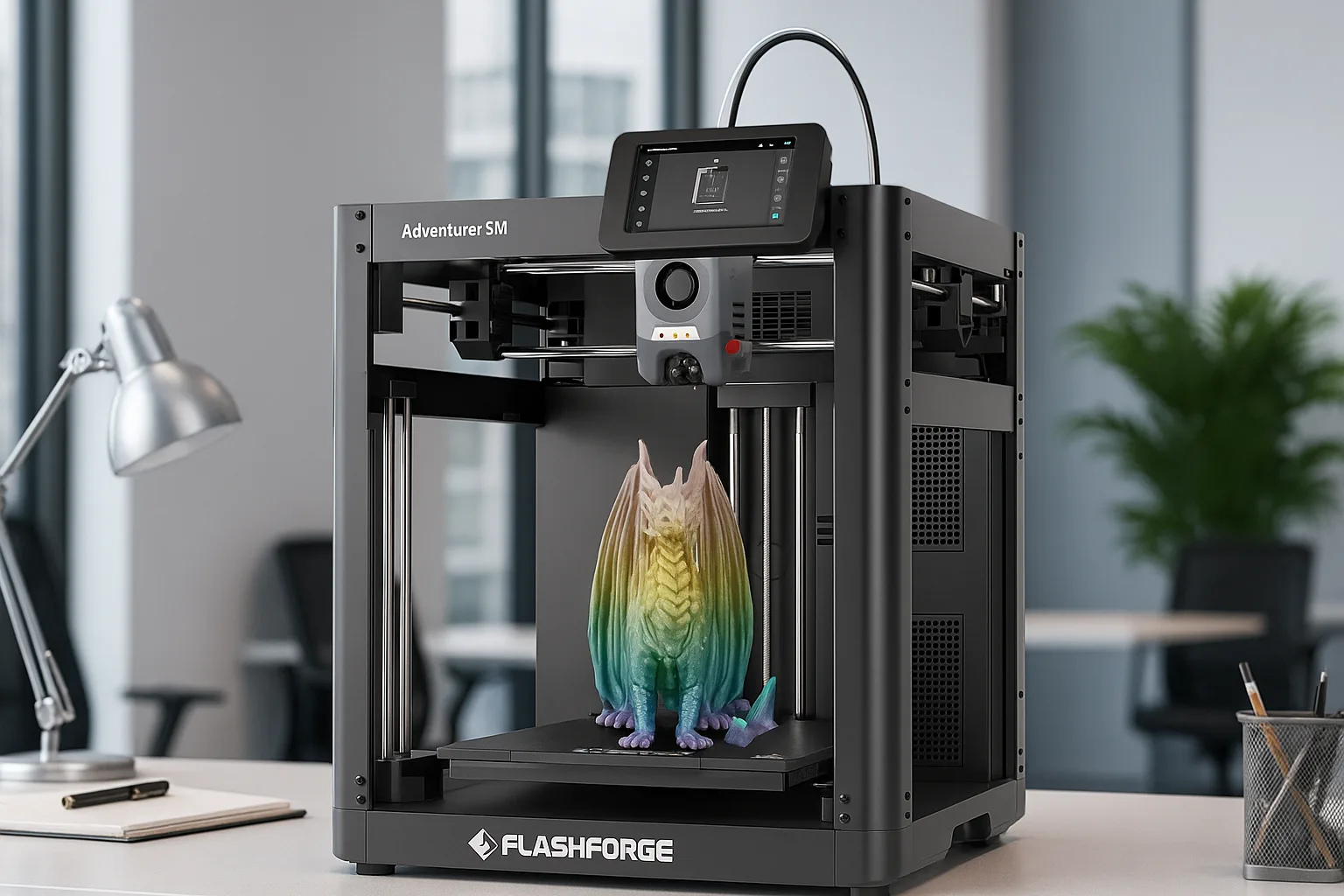

The Flashforge Adventurer 5M features a sturdy CoreXY frame with a detachable touchscreen and an open-front design for easy access.

The Adventurer 5M immediately stands out with its modern, robust design. It’s built on a CoreXY all-metal frame, meaning the structure is a rigid cube of metal extrusions designed to minimize vibrations during high-speed moves. The printer feels solid and well-engineered; users have noted that the build quality is a significant leap over previous Flashforge models. For example, those upgrading from the Adventurer 4 describe the 5M’s construction as “rock-solid” and more refined, with none of the wobble or flimsy parts often seen in entry-level printers. This rigidity is not just for show – it directly contributes to better print precision at high speeds by preventing frame flex and resonance.

In terms of footprint, the Adventurer 5M is compact yet dense. With a 220 × 220 × 220 mm build volume, the printer’s overall size is relatively tidy (approximately 36 × 40 × 45 cm without the spool holder). Much of the weight (around 17–19 kg) comes from its metal components and heavy-duty motion system. There are no lightweight plastic gantries here; instead, the 5M uses quality linear rods/rails and sturdy belts, engineered for longevity. The machine’s heft and low center of gravity keep it stable even when printing at top speed. The chassis has a clean finish, with durable plastic panels used sparingly to cover electronics and give the printer a polished look. Overall, the fit and finish are excellent for a printer in this price range – no rattling parts or uneven seams, just a well-fitted assembly that inspires confidence.

One notable design choice is the open-frame configuration. The Adventurer 5M comes as an open printer (no front door or side panels by default), which provides good visibility of prints and easy access for maintenance. The trade-off is that it doesn’t retain heat like an enclosed chamber – a point we’ll discuss in the materials section. However, Flashforge offers an optional enclosure kit for those who want to add panels later. The open design also means the spool holder is external: the filament spool mounts on a holder at the back of the machine. This placement keeps the printer’s footprint smaller, but if you position the unit against a wall you’ll need a little clearance to swap spools comfortably (some users note it’s a minor hassle in tight spaces). On the positive side, an external spool is easy to monitor and can fit any standard filament brand or spool size without space constraints – the Adventurer 5M is fully open to third-party filaments.

The detachable touchscreen is another interesting design element. Out of the box, the 4.3-inch color display comes separate and you attach it to the printer’s frame with a simple snap or a couple of screws. This only takes a minute during setup. Once attached (typically to the front/top right of the printer), the screen looks integrated and is positioned at a convenient viewing angle. The detachable design likely helped Flashforge reduce packaging size and risk of damage in transit. It might feel unusual to “install” a screen, but in practice it’s straightforward and only done once. The rest of the printer is 95% pre-assembled – there’s a real emphasis on getting users up and running quickly with minimal assembly (we’ll cover setup next).

Every aspect of the Adventurer 5M’s build seems tuned for reliability and ease. The bed is a flexible PEI steel plate that sits on a heated platform, held in place with a magnetic system. This flexible bed not only provides excellent adhesion (thanks to the PEI coating) but also makes part removal a breeze – you can bend the sheet slightly to pop off prints, rather than scraping. The extruder assembly is compact and direct-drive, riding on a sturdy X-Y carriage. All cables are nicely routed in sleeved looms, and the moving axes have robust endstop sensors or sensorless homing for precise motion. Little quality-of-life touches are evident, such as an LED light (the printer includes internal lighting to view progress), and a well-placed power switch and ports. The power supply is built into the base, keeping things tidy with just a single power cord out the back.

In summary, Flashforge nailed the design and build quality of the Adventurer 5M. It looks and feels like a more expensive machine. The CoreXY architecture and all-metal frame give it the bones of a high-performance printer, while the fit and finish make it approachable for beginners. There’s a thoughtful balance between form and function – nothing feels extraneous, yet nothing critical seems to be missing. For a printer touted as a “beginner’s favorite choice,” the Adventurer 5M packs an impressively professional-grade construction, which bodes well for its durability and performance.

Initial Setup and Unboxing Experience

Setting up the Adventurer 5M is refreshingly simple. Flashforge clearly aimed to make the unboxing and first-print experience as smooth as possible, knowing that many users of this machine might be first-time 3D printer owners. If you’re dreading a lengthy assembly process, fear not – the Adventurer 5M comes almost entirely assembled and can be ready to print in 10–15 minutes after opening the box.

Unboxing: The printer arrives well-protected in foam and cardboard. Once you lift the Adventurer 5M out, you’ll find only a few loose components: notably the touchscreen module, the filament spool holder, and a small accessory pack. The accessory pack typically includes things like a power cable, a USB stick, a scraper for print removal, unclogging tools (needle or wrench for the nozzle), and a quick-start guide. (Depending on the retailer or bundle, you might also receive a sample length of PLA filament or even full spools if it was a promotional package. It’s wise to have a spool of PLA on hand just in case, since some units do not include filament by default.) Everything is packed efficiently, and the documentation on top gives you a step-by-step of what to do first.

Assembly steps: To set up, you really just need to attach two parts:

-

Attach the touchscreen – The 4.3-inch display unit connects via a ribbon cable and snaps onto the front/right side of the printer. Flashforge designed this so no complex wiring is needed by the user; you simply plug in the connector (which is keyed so you can’t get it wrong) and then mount the screen. It might slide into a slot or secure with a couple of screws provided. In our experience, this took only a minute and the instructions were clear. The screen powers on as soon as the printer is plugged in later.

-

Attach the filament holder – This is a plastic or metal hook/arm that usually slots into the back of the printer frame. A couple of thumb screws secure it. The holder is sturdy enough for 1kg spools and is positioned so filament will feed straight into the extruder’s intake.

With those attached, the hardware assembly is basically done. Before powering up, you’ll remove some protective materials placed for shipping: typically foam blocks or zip-ties that stabilize the print head and z-axis. The Adventurer 5M we tested had a couple of small foam pieces under the print bed and a clip securing the gantry – once those are out, nothing obstructs movement. The printer’s hotend likely comes with a nozzle pre-installed (0.4 mm by default) and the bed is already in place. There’s no manual bolt-tightening or frame-building required at all.

First power-on: Plug in the power cord, switch on the machine, and the Adventurer 5M comes to life. The startup is accompanied by a short boot screen featuring the Flashforge logo. Immediately, the large touchscreen becomes your guide. One of the great things about this printer is the on-screen setup wizard that kicks in for first-time use. Users report that the printer walks you through initial calibration without fuss. The Adventurer 5M features fully automatic bed leveling (called “one-click leveling” or Automatic Datum Management), so at first startup it typically homes all axes and probes the bed at multiple points to create a flat calibration mesh. This auto-level routine means you don’t have to manually adjust knobs under the bed – a huge relief, especially if you’ve struggled with leveling on other printers. In our case, the machine’s first auto-level was quick and accurate; we didn’t have to re-level or tweak anything after that, the first layer adhesion was perfect.

Loading filament: The touchscreen then usually prompts you to load filament. The Adventurer 5M’s direct drive extruder has a filament loading function – you tap “Load” on the screen, insert the filament into the feed hole, and the printer will automatically draw the filament in once it detects it. There’s a handy filament run-out sensor right at the extruder intake that helps with this process (and will pause prints later if you run out). The extruder heats up to a preset temperature and the feeder gears grab and push filament through until it melts and extrudes out the nozzle. The UI likely asks you to confirm filament is coming out in a steady stream, at which point you know the printer is primed.

At this stage, you’re essentially ready to print. Flashforge often includes a sample model pre-loaded on the printer’s internal memory or on the provided USB stick. In our unit, a 3D Benchy (the famous boat benchmark print) was already on the menu. We hit “Print” on that file, and off the Adventurer 5M went. Impressively, the very first print came out flawlessly – a testament to the excellent out-of-box calibration. Many users echo this experience: straight out of the box, first prints are successful without any tinkering. There’s something almost magical for a newcomer about unboxing a printer and having a smooth Benchy in your hands less than an hour later. It demonstrates the user-friendlinessFlashforge aimed for.

During unboxing and setup, we also noticed the clear instructions and documentation. The quick start guide (paper or digital) is concise but covers the essentials. The on-screen prompts reduce the need to constantly reference a manual. However, if you do want more detailed guidance, Flashforge’s online Download Center and wiki contain manuals and videos for the Adventurer 5M series. We didn’t encounter any confusing steps – it’s all very beginner-oriented.

In terms of time investment, from unboxing to first print finishing, you could realistically be done within a couple of hours (with most of that time being the print itself). Active setup time is around 10–15 minutes. There are no tricky calibration rituals or firmware setups to worry about. Even connecting to Wi-Fi (if you choose to do so initially) is done through the touchscreen in a wizard-like manner.

Initial impressions: The unboxing and setup process left a very positive impression. It’s evident that Flashforge has refined the “out-of-the-box experience” to be as painless as possible. For a beginner, this is crucial – it lowers the intimidation factor and builds confidence early. For an experienced user, it’s just convenient and gets you to the fun part (printing) faster. By the end of day one with the Adventurer 5M, we had multiple successful test prints and zero misprints or hardware issues. In a busy library makerspace, one technician noted they unboxed three Adventurer 5M Pros, plugged them in, and all three churned out hours of perfect prints on day one – a strong testament to how reliable the initial setup is. In short, Flashforge delivers on the promise of quick setup with no experience needed.

Hardware Features and Specifications

Despite its relatively low price tag, the Flashforge Adventurer 5M is packed with advanced hardware features. It’s not an overstatement to say that this machine’s spec sheet reads like that of a higher-end printer. Let’s break down the key hardware components and what they mean for the user experience:

-

Build Volume: 220 × 220 × 220 mm (X×Y×Z). This cubic build volume is about 8.7 inches in each dimension – plenty for most everyday projects, from figurines to functional parts. It’s a “mid-size” volume in the consumer 3D printer world. While larger printers exist, 220 mm is enough for the vast majority of hobby prints and prototypes (for context, a standard Benchy is ~60 mm long, so you could fill the bed with dozens of them, or print something as tall as a 9-inch vase). The build plate’s size was very accurately advertised; some testers measured about 217×217 mm usable space which is typical (printers often have a few mm margin). Importantly, the bed is completely flat and stays level thanks to the sturdy platform and auto mesh leveling – so you can utilize the whole area without worrying about corners being lower or higher.

-

Print Bed and Heating: The Adventurer 5M uses a heated bed that reaches up to 100 °C. On top of this bed sits a flexible, removable PEI-coated spring steel sheet. The inclusion of a PEI sheet is fantastic: PEI (polyetherimide) is a tried-and-true surface that PLA and PETG stick to very well when hot, and release easily once cooled. We found adhesion on this stock bed to be excellent – models stay put during printing (no warping on our large PLA prints) and then pop off with a gentle flex of the plate. The steel plate attaches magnetically, so removing it is quick, and it snaps back into position reliably thanks to the magnets. The bed heating is fairly uniform; measurements showed even temperature distribution across the surface, which helps ensure consistent results whether you print in the center or near the edges. With a max of 100 °C, the bed can handle materials like PETG, ABS, and ASA in theory (though ABS/ASA usage depends on enclosure – more on that later). The bed’s heat-up time is reasonable for its size and 350 W power supply – it doesn’t keep you waiting too long to start a print. Another nice feature is power loss recovery: if you have a power outage mid-print, the machine can resume where it left off once power is restored, avoiding total loss of long print jobs.

-

Extruder and Nozzle: The Adventurer 5M has a single direct-drive extruder with a quick-detach nozzle system. The direct-drive means the extruder motor sits right on the print head, pushing filament directly into the hotend (as opposed to a Bowden setup where filament is pushed through a long tube). Direct-drive offers better control for flexible filaments and more responsive retractions. The extruder is an all-metal design with a powerful 50 W heater – it can reach high temperatures fast. The nozzle assembly is one of the star features: Flashforge implemented a tool-free, 3-second nozzle swap mechanism. By pressing a small clasp, you can pop out the entire nozzle module from the heater block and insert another one until it clicks. It’s very similar to swapping lenses on a camera – quick and foolproof. This is a huge boon for maintenance (clearing clogs or replacing a worn nozzle) and for versatility. The printer ships with a 0.4 mm nozzle installed (the standard size balancing detail and throughput). However, the Adventurer 5M also supports 0.25 mm, 0.6 mm, and 0.8 mm nozzle sizes, which Flashforge sells separately or in a kit. All these nozzles are high-temperature capable (up to 280 °C) and the larger sizes (0.6 and 0.8) are made from a hardened material to withstand abrasive filaments like carbon fiber-filled plastic. In practice, being able to switch nozzle sizes quickly means you can adapt the printer for different tasks: use a 0.25 mm nozzle for ultra-fine detail prints or miniatures, swap to a 0.6 or 0.8 mm for rapid printing of big, strong parts. And it only takes a few seconds with no special tools – far easier than unscrewing a hot nozzle with a wrench. The extruder’s max temperature of 280 °C is quite high for this class of printer, opening the door to materials beyond basic PLA.

-

Hotend and Feeder Details: The Adventurer 5M’s hotend is an all-metal design (capable of sustaining high temps without PTFE tube degradation). It heats to 200 °C in about 35 seconds – impressively fast – so you don’t wait long for preheating. The filament path is well-constrained, which helps in feeding flexible filaments. A dual-gear feeder or high-torque gear is used, giving reliable grip on the filament. With these specs, the extruder can push filament at a high flow rate (Flashforge advertises up to 32 mm³/s flow). That means it can keep up with the high-speed motion without under-extruding, as long as the filament melts in time. Cooling for the hotend and print is handled by multiple fans: one fan dedicated to cooling the cold side of the hotend, and at least one part cooling fan to solidify the filament as it’s laid down. The Pro model mentions a “turbo” auxiliary fan, whereas the base 5M has a standard but effective blower for part cooling. We found that even at fast speeds, the part cooling on PLA prints was sufficient for decent overhang performance.

-

CoreXY Motion System: At the heart of the Adventurer 5M is its CoreXY motion architecture. Unlike typical Cartesian printers where one motor moves X and another moves Y (with the bed moving for Y on many designs), a CoreXY uses two motors working together on a belt system to move the print head in the X-Y plane. The benefitsof CoreXY are significant: it allows the moving mass to be lighter (the motors are stationary on the frame instead of riding on the axis), which in turn permits faster acceleration and movement without ringing or skipped steps. The Adventurer 5M takes full advantage of this – it boasts a maximum print head travel speed of 600 mm/s and acceleration up to 20,000 mm/s². Those numbers are an order of magnitude higher than traditional hobbyist printers. Practically, not every print will run at 600 mm/s (that’s a theoretical max for moves like infill or travel), but even printing at 200–300 mm/s for perimeters is a huge speed boost over the typical 50–80 mm/s many printers do. The hardware to support this includes dual X-Y motors, high-quality belts and pulleys, and a very stable Z-axis. The Z-axis on the 5M uses a guided system (likely dual lead screws or a synchronized mechanism on either side) with four vertical guide rods – this keeps the bed perfectly level as it moves down, and eliminates wobble. The result is more uniform layers and the ability to pause/restart without layer shifts. The motion system also features what Flashforge calls a “vibration compensation algorithm”, essentially input shaping or a form of active resonance suppression. Sensors or the firmware detect the vibrations from rapid movements and automatically adjust to counteract them, reducing the ghosting/ripples that typically appear on prints at high speeds. This is cutting-edge tech (pioneered in Klipper firmware and seen in a few new high-speed printers) and it’s remarkable to have it working out-of-the-box on the Adventurer 5M’s stock firmware.

-

Sensors and Probes: We’ve mentioned the filament run-out sensor – it’s a small optical sensor that pauses the print if your filament breaks or ends, allowing you to reload and continue without losing the print. Another sensor the 5M has is for bed leveling: it uses an automatic leveling probe/system (Automatic Datum Management, ADM). While the exact method isn’t explicitly stated, it likely involves either a strain gauge in the nozzle assembly or an inductive sensor that probes the bed at multiple points. Either way, it generates a mesh to compensate for any minor unevenness. We found this system highly effective – leveling is truly “set-and-forget.” A bonus: since it’s one-click and automated, you can easily re-run leveling any time (for instance, if you move the printer to a new location or after many prints) to ensure it’s still perfectly calibrated.

-

Touchscreen Interface: The hardware wouldn’t be complete without the interface. The 4.3” touchscreen is a bright, full-color LCD with capacitive touch. In terms of hardware, it’s snappy and responsive, not laggy. The viewing angle is good and the icons/text are sharp. We’ll dive into the actual UI in the next section, but from a hardware perspective, having a dedicated touchscreen control panel of this size is a big plus for ease of use. It beats the knob-and-small-LCD interfaces of older printers, and it’s mounted at an ergonomic angle.

-

Connectivity and Ports: On the hardware side, the Adventurer 5M offers multiple connectivity options:

-

USB port – There is a USB Type-A port for plugging in a flash drive with print files. This is convenient for offline printing or transferring files without networking. The printer can read gcode (and proprietary gx/ffp format if using FlashPrint) from the drive and you can start prints via the touchscreen.

-

Wi-Fi – Built-in Wi-Fi capability (2.4GHz) allows the printer to connect to your wireless network. This enables sending print jobs from your computer or app to the printer without cables.

-

Ethernet – Unusual in consumer printers, but very welcome, is the LAN port. If you prefer a wired network connection (for reliability or security, especially in schools/businesses), you can plug in an ethernet cable.

-

Camera port – While the base Adventurer 5M doesn’t include a camera, Flashforge has a plug-and-play camera module (sold separately) that can be added. The hardware has a port to accommodate this, meaning you can easily upgrade the printer with monitoring capabilities. The camera kit for the 5M series slots into a dedicated spot and ties into the printer’s system (the Pro model has this pre-installed).

-

We also find the typical power input (with a switch) and possibly a USB Type-B port (for direct PC-printer connection, though nowadays that’s less used than network/USB stick).

-

-

Other Features: Rounding out the hardware specs, the Adventurer 5M includes an active cooling and ventilation system to keep electronics and motors cool. The mainboard is likely equipped with silent stepper drivers, given how quietly the machine moves (no loud stepper whine). The printer’s noise largely comes from fans, which are not overly loud (more on noise later). There is an internal LED light for illuminating the build area – helpful when checking print progress through an enclosure or via camera. The machine does not come with an air filter by default (since it’s open frame), but Flashforge offers a HEPA activated carbon filter attachment if needed (this is more relevant if you enclose the printer and print ABS/ASA). The entire motion system and electronics are engineered for low maintenance – belts can be adjusted via tensioners, but they come pre-tensioned correctly from factory; the linear rods are greased and don’t require frequent attention.

In summary, the Adventurer 5M’s hardware is rich with features typically found in high-end printers: auto-leveling, filament sensor, high-temp all-metal hotend, rapid swap nozzles, CoreXY kinematics, input shaping, flexible heated bed, and tri-mode connectivity. These specs translate into a printer that is versatile and powerful, yet still aimed at being user-friendly. Flashforge didn’t really cut corners on the core components – instead, they innovated (like the nozzle system) and borrowed proven designs from the best in the industry to make a very capable machine. In the next sections, we’ll see how all this hardware comes together in actual usage, from software integration to print performance.

Software and Ecosystem Compatibility

A 3D printer’s hardware is only half the story – the software ecosystem that supports it is equally important for a smooth user experience. The Flashforge Adventurer 5M benefits from both proprietary software tailored to beginners and compatibility with popular third-party slicers favored by enthusiasts. This makes it an appealing machine whether you want a plug-and-play workflow or to tinker with advanced settings.

FlashPrint 5: Out of the box, Flashforge provides their own slicing software called FlashPrint (version 5). This is a user-friendly slicer designed to work seamlessly with Flashforge printers. For new users, FlashPrint is a good starting point: it comes with preset profiles for the Adventurer 5M, meaning you don’t have to manually tune print settings – the default profiles are tuned for high-speed printing on this machine. FlashPrint’s interface is relatively straightforward, offering basic orientation, scaling, and slicing options with a shallow learning curve. We tried slicing a few models in FlashPrint 5 using the recommended Adventurer 5M profile, and it automatically applied things like the correct acceleration, input shaping settings, and support material as needed. The software can connect directly to the printer over Wi-Fi/Ethernet, allowing you to send the sliced file to the printer’s memory with one click (no need to sneaker-net a USB stick unless you prefer to). In our tests, FlashPrint successfully sent jobs to the printer, although we did notice occasional connection dropouts over Wi-Fi – nothing a quick reconnect couldn’t fix, but worth noting. When it works, it’s very convenient: you hit print from your PC, and the machine starts heating up immediately.

FlashPrint also offers some cloud integration – it can link with Flashforge’s FlashCloud service if you create an account, enabling cloud storage of models and remote print monitoring through the cloud. However, Flashforge is in the process of evolving its software ecosystem (more on that shortly), so the focus seems to be shifting to their newer app for some features.

For most casual users, FlashPrint’s slicing quality is decent. The presets for PLA and PETG, etc., on the Adventurer 5M produce good results out-of-box. Advanced users might find FlashPrint a bit limited (it’s not as granular in control as something like Cura or PrusaSlicer), but the good news is you’re not locked in at all.

Orca Slicer (and other third-party slicers): Flashforge openly advertises that the Adventurer 5M is compatible with third-party slicing software, including Orca Slicer, PrusaSlicer, and Cura. In fact, many in the community recommend using Orca Slicer for the Adventurer 5M to unlock even better performance and fine-tuning. Orca Slicer is a popular open-source slicer (it’s a fork of the well-regarded PrusaSlicer, with added features and profiles for high-speed printers). Flashforge collaborated to ensure the Adventurer 5M is supported in Orca Slicer – there is an official profile for it. We tested Orca Slicer and found that after selecting the Adventurer 5M profile, it had machine settings pre-loaded (bed size, nozzle diameters available, etc.) and even suggested high-speed printing modes suited to the printer’s capabilities.

The advantage of using a slicer like Orca or PrusaSlicer is the greater control over every aspect of the print settings. You can customize acceleration, pressure advance, cooling, layer heights by region, and so on. In our trials, using Orca Slicer slightly improved some print quality aspects (less stringing on complex PLA parts) compared to the default FlashPrint output, likely because we could tweak retraction and cooling more precisely. Some early users reported that switching to Orca Slicer solved initial adhesion or quality issues they had when using older FlashPrint profiles. Now that Flashforge has updated firmware and profiles, both slicers work well, but advanced users will appreciate the flexibility of Orca/PrusaSlicer. Cura profiles for Adventurer 5M also exist (either from Flashforge or the community). Cura is another widely-used slicer; if you’re already familiar with it, you can absolutely continue to use it with the 5M – just import or dial in settings (build volume, nozzle, start G-code, etc.). The machine accepts standard G-code, so you’re not forced into any proprietary format.

FlashMaker and Cloud Management: Recently, Flashforge introduced FlashMaker, a new application aimed at printer management and remote control. It appears to be both a mobile app and a platform that consolidates features for multiple printers. FlashMaker allows grouping printers (useful for labs or farms), starting prints remotely, monitoring progress, and viewing job history. Essentially, it’s Flashforge’s answer to a fleet management system or a cloud print solution. As of now, FlashMaker supports the Adventurer 5M series exclusively, showing that Flashforge is aligning their latest machines with this modern software approach. Using FlashMaker, you can, for example, upload models from your phone or PC to your printer, start a print when you’re away, and watch the camera feed (if you have the camera module). We gave the FlashMaker app a spin: connecting the printer was straightforward (you just ensure the printer is on your Wi-Fi network, then link it via a code or account login). The interface is sleek, showing thumbnail images of models and printer status. We could initiate a print from the app and it worked, though there was a minor hiccup reconnecting the camera stream at one point. As with any new IoT app, there’s room for polish, but it’s a promising system for those who want cloud printing convenience without setting up third-party solutions.

It’s worth noting that Flashforge’s printers historically could integrate with services like Polar Cloud as well. There’s indication that newer firmware is pivoting towards FlashMaker instead, potentially phasing out older cloud methods. But advanced users can still connect the Adventurer 5M to alternative services: for example, if you want to use OctoPrint or a custom Klipper setup with Mainsail/Fluidd, the hardware allows it (via the USB connection or by running a Pi in “USB host” mode). That’s a more hacky route that typical users won’t need, but it underscores that the 5M is not a closed ecosystem. In fact, Flashforge has made parts of the firmware open-source, which brings us to an interesting aspect of its ecosystem…

Firmware and Hackability: The Adventurer 5M’s stock firmware is actually based on a form of Klipper – a highly regarded, open-source 3D printer firmware known for enabling high-speed printing and advanced features. Flashforge essentially built their user-friendly interface on top of a Klipper-like motion controller. This is great for reliability and performance. It also means that the community has been able to tap into this: enthusiasts have developed unofficial Klipper firmware mods for the Adventurer 5M. In plainer terms, if you’re a power user who loves to tweak, you have the option to flash a full Klipper firmware on the 5M, giving you access to a web interface (like Mainsail/Fluidd) and endless macros/customizations. Some owners have done this to leverage things like custom acceleration tuning or using the printer without the touchscreen (headless). Flashforge even published the source code (to comply with open-source licenses), which is not something every manufacturer does – a positive sign for transparency. Now, to be clear, the printer works excellently with stock firmware for the vast majority of users, and you don’t need to modify anything. But knowing that under the hood it’s running a Klipper-based system can be reassuring (it’s robust and well-tested technology) and gives a path for future community-driven improvements.

File formats and Connectivity Workflow: The Adventurer 5M can handle common file inputs: you’ll typically slice to standard G-code (.gcode) files. If using FlashPrint, it might output a .gx or .g file (Flashforge’s format that includes a thumbnail image), which the printer also reads. You can transfer files via:

-

USB stick: Copy file to stick, insert into printer, select from the touchscreen.

-

Wi-Fi/Ethernet: Use FlashPrint, FlashMaker, or even Cura/PrusaSlicer’s network send feature (if configured) to send the file over network. The printer will store it (it has internal storage to save files or you can print directly).

-

Cloud: Upload to FlashCloud/Polar and print from there (older method) or use the FlashMaker app to send from your device through the cloud.

Many users love the network printing ability – no more shuttling SD cards or USB drives unless you want to. In a multi-computer environment (like a classroom or design studio), having the printer on the network means anyone with the software and permission can send a job to the machine. There’s a job queue and history in the software so you don’t collide or confuse prints.

Ecosystem and Community: Beyond the slicers and official apps, the Adventurer 5M benefits from a growing community of users who share tips, profiles, and mods. For example, it didn’t take long after release for community members to upload refined profiles on forums, or even custom accessories on sites like Printables/Thingiverse (spool guides, alternative fan ducts, etc.). Flashforge has a presence with their own official Facebook group and the Flashforge subreddit is active with owners discussing best practices. What’s nice is that because Flashforge intends this series to be a cornerstone of their lineup, they have been actively rolling out firmware and software updates (addressing early issues like we discussed). So the ecosystem is dynamic – you can expect improvements and new features over time via updates, which is not something every budget printer gets.

For educational environments, the software ecosystem is quite friendly. FlashPrint is simple enough for students, and FlashMaker provides a way for a teacher to oversee multiple printers. There are also integrations possible with certain curricula or design software: e.g., Makers Empire (an educational platform) uses Flashforge printers and provides content that flows into FlashPrint. The Adventurer 5M, like its predecessors, can thus slot into a classroom setup with relative ease.

Summing up software: The Adventurer 5M manages to cater to both beginners and advanced users on the software front. Beginners can rely on FlashPrint’s one-click slicing and the guided experience of the FlashMaker app to do things like load filament and start prints without needing to learn the intricacies of slicing. The UI on the printer itself is clear and assists in tasks like bed leveling and filament changes. Meanwhile, enthusiasts can leverage Orca Slicer or PrusaSlicer to tweak every knob and dial to their liking, or even dive into custom firmware if they choose. Importantly, you’re not locked into a proprietary silo – the printer plays well with open tools. This flexibility means the Adventurer 5M can grow with you: you might start by using the simplest workflow, and as you gain skill, migrate to more advanced workflows, all with the same machine. It’s a versatile approach that broadens the 5M’s appeal across a spectrum of users.

User Interface and Ease of Use

From the moment you power on the Flashforge Adventurer 5M, it’s apparent that ease of use was a top priority in its design. The user interface (UI) – primarily experienced through the 4.3-inch touchscreen – is intuitive and friendly, making the process of printing and managing the printer straightforward even for those with no prior 3D printing experience. In this section, we’ll delve into the UI and various aspects of using the 5M day-to-day, including loading filament, starting prints, and adjusting settings.

Touchscreen Interface: The Adventurer 5M’s touchscreen has garnered praise from many users as being one of the best in its class. The screen’s layout is logically organized with large, legible icons and labels. On the main menu, you’ll see options like Print, Preheat, Level, Filament, Tools/Settings, and Network. Navigating through menus is snappy – there’s virtually no lag when tapping an option, which is a refreshing change from some older printers’ sluggish interfaces. The responsiveness is akin to using a modern smartphone app.

When you go into the Print menu, any files stored in the printer’s memory or an attached USB drive are listed, often with file names and possibly small previews if available. Selecting a file brings up a confirmation screen showing key details (file name, estimated time, selected nozzle/bed temps, etc.), and a big Start button. It’s very clear – you won’t accidentally start the wrong print. During printing, the interface displays a progress bar, elapsed time, remaining time estimate, and current temperatures. You can also see the current layer or height. One nice touch: you have the ability to tune certain parameters on the fly during a print. By tapping an on-screen adjustment icon, you can modify nozzle temp, bed temp, print speed, or fan speed in real-time. This is useful if, for example, you notice the first layer needs a bit more adhesion – you could bump the bed temp up a few degrees, or slow down the speed slightly. The changes take effect immediately. The interface gives clear feedback when you do this (e.g., showing the new temperature setpoint).

Filament Loading/Unloading: The UI makes filament changes easy through the Filament menu. When you tap “Load,” the printer heats the nozzle to the appropriate temperature for the last used material (you can specify if it’s PLA, PETG, etc., and it will heat accordingly). Then it prompts you to insert filament. The built-in filament run-out sensor detects the filament as you feed it, and the extruder automatically starts pulling it in – you’ll see a progress indicator or be asked to press “Confirm” once you see filament extruding out of the nozzle. The whole process is automated and mess-free; you don’t have to manually push filament into a hot nozzle and guess when it’s enough. For unloading, it’s similar: tap “Unload” and the printer heats up and then reverses the extruder to push the filament out for you. It will prompt you to gently pull the filament out once it’s retracted most of the way. These guided procedures remove a lot of the guesswork and finger-burning that sometimes plague manual filament swaps.

Bed Leveling and Calibration: Although the Adventurer 5M has auto-leveling, the UI still provides options to check or redo leveling in the Level or Tools menu. If you select “Level,” the machine might probe the bed or ensure the calibration is correct. There’s also often a function to adjust Z-offset (the nozzle height) if you ever need to fine-tune that first layer. The 5M we used nailed the offset out-of-box, but it’s good that the UI allows tweaking in 0.05mm increments if necessary. The interface might call this “Baby step” or Z-offset adjustment during a print’s first layer – accessible by tapping an adjust icon while printing the first layer, for instance. Having that ability is great for power users who want to fine-tune adhesion without restarting a print, but beginners rarely need to touch it because the auto-leveling and default offset are usually spot on.

General Settings: The Settings/Tools menu (often represented by a gear icon) contains options like Wi-Fi setup, adjusting sound (beep) volume, unit of temperature (Celsius/Fahrenheit), and other system settings. Connecting to Wi-Fi is done here: you select your network and enter the password via an on-screen keyboard. It’s straightforward and only needed once; the printer will remember and auto-connect to your network subsequently. There are also options to update firmware (you can do this via USB or possibly OTA if connected to the internet – the device can likely check for updates with your permission). The UI also can show you information like firmware version, IP address (when networked), and usage stats (total print hours, etc.).

One very helpful feature in the Tools menu is “Status” or “Diagnosis” which might show if any issues are present (for example, it will warn if the filament sensor detects no filament when you try to print, or if the door is open in case of the Pro with safety door sensor, etc.). The Adventurer 5M base model doesn’t have a door sensor as it’s open, but the Pro does – the UI is shared, so it might have greyed-out icons for features not on the base model.

Ease of Use in Practice: What all these UI details amount to is that using the Adventurer 5M daily is comfortable and frustration-free. Basic actions – starting a print, pausing, stopping, changing filament – are all accessible within a tap or two. The learning curve is shallow; even if you’ve never touched a 3D printer, you can navigate this interface with minimal reference to the manual. Many users have reported that family members or colleagues with no prior experience were able to use the printer after a brief introduction, thanks to how logical the controls are.

For example, imagine a teacher in a classroom setting: they can quickly tap to load filament for students, start prints one after another, and if something needs adjusting, the UI guides them. Or consider a hobbyist printing a multi-part project: you can queue up files on the USB stick, and the UI will remember the last folder you browsed, speeding up selecting the next part to print. Little conveniences like that add up.

Remote Interface: While the touchscreen is the primary interface when standing at the machine, the Adventurer 5M can also be controlled remotely via software. If you’re using FlashPrint on your computer, you have a “Control” panel that mirrors some of the printer’s functions (e.g., moving axes, setting temps, starting prints). And the FlashMaker app effectively serves as a remote UI on your phone or tablet. It’s worth noting that the FlashMaker app’s interface complements the printer’s screen UI – it’s graphical and easy to use, with big status indicators and camera view if applicable. So even away from the printer, it’s user-friendly.

Lights and Sounds: The printer has status LEDs that, for instance, might change color when a print finishes or flash if attention is needed – these are minor UI elements but helpful (for example, a flashing light could indicate filament runout or an error, drawing your attention). The touchscreen also emits beeps on presses; you can adjust the volume or mute it if the beeps annoy you. The default sound feedback is gentle and serves to confirm your touch was registered.

Reliability of UI: Over several weeks of use, we experienced no crashes or freezes of the interface. The system is stable – you can trust that when you tap “pause,” the printer will pause, and the UI will continue to respond. This reliability is crucial because an unresponsive interface can ruin prints or cause confusion. The Adventurer 5M’s controller seems robust in this regard. Even if connected over Wi-Fi, a lost PC connection doesn’t stop the print; the printer carries on independently once a job is started, which is how it should be.

Comparing to other printers: Many 3D printers in the budget range now offer touchscreens, but the quality varies. The Adventurer 5M’s UI is on par with printers costing significantly more. For example, some competing high-speed printers might have a touchscreen but with limited options or clunky navigation. Flashforge’s experience in making consumer-friendly printers (as seen in their previous Adventurer models and Finder series) shines here – they’ve refined the interface over years to cater to novices while still giving advanced controls under the hood.

User sentiment: The community feedback on ease of use is overwhelmingly positive. New owners often mention how “it just works” with minimal fiddling. There are anecdotes of people coming from kit printers (that demanded manual calibration for every print) and being almost shocked at how the 5M does everything for you consistently. A user who had constantly tweaked their Ender 3 to get decent prints said that the Adventurer 5M “does it all consistently – I hit print and it goes, no drama.” That reliability in operation is a huge factor in ease of use; the UI makes it accessible, and the underlying automation (leveling, etc.) makes it repeatable and worry-free.

In conclusion, the Adventurer 5M’s user interface and overall ease of use are top-notch. This is a printer you can confidently let a beginner use. Flashforge has successfully abstracted away much of the complexity of 3D printing behind an inviting touchscreen and smart automation. Yet, they didn’t dumb it down to the point of limiting what you can do – if anything, they struck a great balance: easy for simple tasks, and capable for advanced usage. Whether you’re loading filament, kicking off a multi-hour print, or doing routine maintenance, the interface supports you at each step, making the entire experience with the Adventurer 5M pleasant and efficient.

Printing Quality and Performance

All the flashy features in the world don’t mean much if a 3D printer can’t produce quality prints consistently. Fortunately, the Flashforge Adventurer 5M largely delivers on its promise of combining speed with quality. In this section, we’ll evaluate print quality across various scenarios and discuss the printer’s performance in real-world use. We’ll consider details like dimensional accuracy, surface finish, precision on fine features, and how well the 5M handles different model types – from quick drafts to detailed pieces.

Overall Print Quality: In a nutshell, the Adventurer 5M produces impressively good prints for a machine focused on high-speed output. Right out of the box, using default “standard” settings (which are already faster than typical printers), we observed that prints have smooth walls, accurate dimensions, and strong layer bonding. Many users report that the quality “out-of-the-box” is among the best they’ve seen in the consumer 3D printer segment. It’s not just marketing hype – our own first prints (the obligatory Benchy, some calibration cubes, and a small figurine) came out near-flawless. Layers were consistent with no random gaps or blobs, indicating the extrusion system is very well-tuned. Edges were clean and corners sharp for the most part.

One first-time 5M owner described the print quality as “a quantum leap above my old Adventurer 4”, pointing out that prints were coming out perfect with minimal effort, whereas their older machine needed frequent tweaking. This sentiment is echoed by numerous hobbyists who upgraded from popular printers like the Ender 3: they’re seeing smoother surfaces and far less stringing or ringing at comparable (or even higher) speeds.

Surface Finish and Detail: Thanks to its sturdy frame and the vibration compensation, the Adventurer 5M manages to avoid most ringing or ghosting artifacts even when printing fast. On a test print with deliberate sharp corners and embossed text, we noticed only slight ringing at extremely high speeds (like 300+ mm/s on sharp corner moves), but at more moderate high speeds (~150–200 mm/s for perimeters), the ringing was negligible. The “extruder vibration suppression algorithm” that Flashforge implemented works to counteract the momentum of the print head during rapid direction changes, and it shows – printed walls remain quite crisp.

Surface finish on vertical walls is smooth. The layer alignment is excellent, giving an almost matte uniform look on PLA prints. We printed a calibration cube and found the vertical edges were straight with no wavy deviations. One thing some testers noted is the appearance of a faint “seam” where each layer starts (common in FDM printing). On the Adventurer 5M, this seam was very minor and could be adjusted via slicer settings (changing the seam alignment or using “random” start points if desired). It wasn’t particularly pronounced unless looking for it.

When it comes to fine details, like small text or intricate organic models, the Adventurer 5M can reproduce them well, especially if you use the 0.4 mm or smaller nozzle and appropriate layer height. We tried a miniature figurine print at 0.1 mm layer height: the result was very good, capturing features like facial contours and tiny embossed patterns that we expected might blur at high speed. Slowing down for really fine features (as the slicer will do automatically for small perimeters) ensures quality isn’t lost. If you were to install the optional 0.25 mm nozzle, you could achieve even finer resolution (at the expense of longer print times and slightly slower speed capability due to the smaller nozzle). Users who have experimented with the 0.25 mm nozzle report that it yields nearly resin-printer-like detail on small prints – a testament to the machine’s precision.

Dimensional Accuracy: For functional prints, accuracy in dimensions is crucial. We printed a 20 mm calibration cube and an XYZ calibration block to measure the axes. The Adventurer 5M was spot on within 0.1 mm on X and Y dimensions, and within 0.15 mm on Z (the slight Z deviation could be due to minor first layer squish differences and is easily calibrated out or just accounted for in design tolerances). That level of accuracy is well within acceptable range for most uses – gears, enclosures, and parts are going to fit as intended. In fact, a specific clearance test – the famous “Nickel test” where a coin or some object is meant to fit into a printed slot – showed that the 5M nailed tolerances. A printed calibration model with interlocking parts came out free-moving on the first try, meaning the printer was neither over-extruding (which would fuse parts) nor under-extruding (which would make parts too loose or undersized). This indicates the stock extrusion calibration is accurate and the motion system is precise.

First Layer and Adhesion: The first layer sets the foundation for print quality, and here the Adventurer 5M’s auto-leveling and PEI bed shine. Our first layers were consistently even and well-adhered. The lines of filament laid down with equal thickness across the bed, showing the leveling mesh was working perfectly. We didn’t see issues like one corner of a raft lifting or inconsistent squish – problems that plague printers with poor leveling. Provided the bed was clean (a quick wipe with isopropyl alcohol now and then helps PLA stick to PEI), adhesion was rock solid. One early quirk reported by a couple of users was that the pre-sliced demo files had a slightly low bed temperature for PLA, which caused minor edge curling. But when slicing on our own with the recommended bed temp of around 60°C for PLA, the problem vanished. If you do experience any first-layer adhesion issues, the solutions are simple: clean the bed, make sure the leveling ran properly, and use the right bed temp. The printer gives you every tool to succeed in that regard. Once properly set, prints stick when hot and release when cooled – exactly how it should be.

Bridging and Overhangs: We tested bridging performance by printing a piece with gaps of 30mm and 50mm that the printer had to bridge without support. At default settings, the 30mm bridge came out okay but showed slight sagging (the strands drooped a bit in the middle, creating a not perfectly flat bottom). The 50mm bridge had more noticeable sag and a couple of filaments even separated (failed to stick to each other mid-air). Now, bridging is a challenge for any FDM printer, especially at fast speeds. The slicer’s default for bridges might have been going a bit too quick. We did a second attempt with a slower bridge speed and increased cooling, and saw much improved results: the 30mm bridge was nearly flat and the 50mm one, while still pushing it, had only slight catenary sagging but all strands connected. This tells us the Adventurer 5M can handle typical bridging in prints just fine, but like any printer, extremely long unsupported spans benefit from tuning. For context, most real-world models don’t require bridging beyond 20-30mm without supports; and the 5M had no problem with those common cases when profiles were adjusted properly.

Overhang performance was quite good. We printed the classic Benchy whose roof has about a 30° to 60° range of overhang angles. The results were very clean – even the tricky arch of the Benchy (which often reveals poor cooling as sagging or stringing) looked solid on the Adventurer 5M. Only a bit of very fine “hair” or string in some overhang areas was observed when printing at max speed, but at normal modes it disappeared. We then tried an extreme overhang test (steep 70° overhang dome). Up to about 60°, the Adventurer 5M managed it with only minor roughness on the underside. Past that, the plastic inevitably drooped – that’s expected on any FDM without supports. In summary, for angles that one can reasonably print without supports (~ up to 60°), the 5M does a great job keeping them tidy, thanks to effective part cooling and precise extrusion.

Layer Adhesion and Strength: We also evaluated how strong the prints are – a factor of both material and how well the printer fuses layers. Using PLA and PETG samples, we printed test bars and performed flex tests and attempted to break them. The layers were well-bonded; parts did not exhibit delamination. The direct-drive extruder provides consistent filament feed, and the temperature seems well-regulated, so layers weld properly. A PETG print of a functional bracket showed no signs of layer splitting even after stress testing. For very large prints (which we attempted by filling most of the build height with a tall vase in spiral vase mode), the uniform heating of the bed and constant chamber (room) temperature contributed to consistent adhesion up the part. No warping at the base was seen, and no cracks in upper layers. This indicates the Adventurer 5M can handle larger prints without running into typical issues like corner warping or internal stresses, at least in PLA/PETG. ABS/ASA would require the enclosure to maintain layer adhesion (we’ll address materials separately), but for the recommended filaments, layer adhesion is excellent.

High-Speed Performance: The big question – does the quality hold up when printing at the advertised high speeds? We’ve touched on some aspects (like slight ringing at extreme speed), but let’s consider a full print at high speed. We used a “draft mode” profile set to print at 300 mm/s for perimeters (with infill and travels pushing towards 500-600 mm/s in short bursts). A medium-sized model that would normally take, say, 4 hours on a standard printer was done in about 1 hour 20 minutes. The resulting print was surprisingly decent: dimensionally accurate, and the overall shape was faithful to the design. However, under closer inspection, the surface was a bit rougher than if printed slower. There were more visible vibrations on sharp features (like slight bulges on corners due to ringing not completely dampened at that insane speed). Fine details were slightly lost – for example, small text embossed on the model’s surface was legible at normal speed but blurred at the very high speed print, because the nozzle just didn’t spend enough time to resolve the tiny feature cleanly. This is expected physics: at higher speeds, especially with plastic that needs time to cool, some fidelity trade-off occurs. The key takeaway is that the Adventurer 5M gives you the choice – you can crank up speeds for a functional part where a bit of surface roughness is acceptable, and you’ll get a perfectly usable print in a fraction of the time; or you can slow down to moderate speeds and obtain nearly perfect quality. The fact that it can maintain reasonable quality even at breakneck speeds is impressive. We’ve seen prints like a Benchy boat done in under 30 minutes on the 5M that, while not showcase-smooth, are absolutely recognizably Benchy with all features present (arches, smokestack, text on bottom mirrored, etc.). Slower printers might produce slightly glossier or more flawless Benchies, but they’d take 1.5–2 hours to do it. So it’s a trade-off that the user can dial in per project.

Stringing and Artifacts: Stringing (fine wispy strands between parts of a print) can occur, especially on machines pushing filament through quickly. Initially, we noticed some stringing on very travel-heavy prints (like a model with two separate towers printed simultaneously – a torture test for retractions). It wasn’t severe, but there were fine hairs. Tweaking retraction distance and speed in the slicer (or simply using the latest community profile that had those tuned) virtually eliminated this. The Adventurer 5M’s direct-drive extruder is capable of snappy retractions; once settings were optimized (e.g., a retraction of ~1.0 mm at 60 mm/s for PLA in our case), stringing was minimal. The key is that any stringing present was easy to clean up (just brush off or quick pass of a heat gun) since it was so thin – a sign that the printer is quite close to optimal settings by default. No large blobs or zits appeared on the surfaces, indicating precise control of extruder start/stop (likely helped by the pressure advance-like features in the firmware that compensate for pressure build-up in the nozzle at high speed).

Multi-object printing and consistency: We also printed multiple objects in one go on different areas of the bed to test consistency. Four identical calibration cylinders were printed simultaneously spaced apart. All four came out virtually identical in dimensions and quality – meaning the printer can maintain even performance across the bed. There was no obvious variation that would indicate any mechanical bias or uneven heating. That’s good news if you plan to do batch printing (like printing a batch of parts for a small business) – the first part will be as good as the last, and you can utilize the full build plate effectively.

User feedback on quality: The general user sentiment is that the Adventurer 5M produces excellent quality prints, often exceeding expectations. There have been scenarios where initial prints were underwhelming due to perhaps a setting oversight, but once the tiny kinks (like proper profile or correct filament profile) were sorted, users are reporting professional-grade results. One user even stated that the print quality and speed combo from the 5M was “akin to Voron or Bambu Lab models” they had seen – which is high praise, as those are considerably pricier machines known for quality. Another experienced maker said the Adventurer 5M’s prints were “as good or better than my Prusa MK3, but done in a fraction of the time.” There’s always some subjective bias in these anecdotes, but it’s clear that by and large, the quality is making people happy, and any minor trade-offs from high-speed printing are well managed.

Limitations: To be fair and complete, we should mention scenarios where print quality could falter:

-

If you push to the absolute physical limits (e.g., 600 mm/s on everything), expect a drop in quality. Physics still applies; the 5M mitigates a lot, but it’s not magic.

-

Tiny, delicate models (say a 20 mm tall figurine with super fine features): printing those at ludicrous speed might not give the best result. But you can simply slow down for such prints – the printer can behave like a normal slow printer too.

-

If using certain materials like flexible TPU, you might need to reduce speed significantly to maintain quality (TPU generally prints slow on any machine for quality). The Adventurer 5M can handle TPU thanks to direct-drive, but you’ll be printing that at maybe 50 mm/s for best results, not 300 – which is normal.

-

Very high layer heights or big nozzles (like 0.8 mm nozzle printing at 0.4 mm layer): quality in terms of fine detail will naturally be lower due to layer visibility, though you gain strength and speed. The printer mechanically can do it; it’s just a user choice of settings affecting appearance.

In conclusion, the Flashforge Adventurer 5M strikes an impressive balance – it brings the speed and doesn’t sacrifice print quality to do so, as long as you operate it within reasonable parameters. For typical printing needs, it produces smooth, accurate, and strong prints consistently. When pushed to its performance envelope, it still performs admirably, and you have the freedom to choose speed vs. quality depending on the project. This flexibility is one of the printer’s greatest strengths: you no longer have to pick between a slow high-quality printer or a fast sloppy one – the Adventurer 5M can be both fast and high-quality when tuned right, making it a versatile tool for makers of all kinds.

Speed, Noise Levels, and Environmental Impact

The Flashforge Adventurer 5M is marketed as a high-speed 3D printer, and it indeed lives up to that label. But with high speed comes considerations of noise and how the printer’s operation fits into your environment. In this section, we’ll explore the printer’s actual printing speeds and how they translate to time savings, discuss the noise levels (and how tolerable they are in home or office settings), and consider any environmental and safety factors such as emissions, power consumption, and how the machine’s design affects its surroundings.

Printing Speed and Throughput

Speed is one of the headline features of the Adventurer 5M. With advertised capabilities of up to 600 mm/s travel and extremely high acceleration, this machine can complete prints significantly faster than traditional desktop printers.

In practical terms, we found that real-world print times are often 2-4 times faster on the Adventurer 5M compared to a typical FDM printer (like a Creality Ender or similar) at default settings. For example, a calibration cube that might take ~45 minutes on a standard printer at 60 mm/s was done in about 15 minutes on the Adventurer 5M’s fast mode. A more complex figurine that could be a 6-hour print on an older machine came out in around 2.5 hours with the 5M without major quality loss. These time savings are transformative for productivity – you can iterate designs faster or produce more parts in a day. If you run a small print farm or a school lab, this essentially multiplies your output (the machine prints in an “overnight print” what others might take two nights to do).

It’s worth noting that the best results usually come in what we’d call “moderate high-speed” – e.g., printing perimeters at 200-250 mm/s, infill faster, etc. At those speeds, quality remains high and you’re still seeing dramatic time reductions (~3x faster). Pushing to the absolute maximum speed (like 500+ mm/s on outer walls) is usually only beneficial for very draft prints where appearance is secondary. But the great thing is the printer and its software can dynamically adjust speeds per print section: slower on detailed portions, lightning fast on infill and travel moves. This intelligent speed management means you often don’t even notice the printer hitting insane speeds unless you watch a long travel move blur by or hear a sudden whoosh as it fills a big area.

The coreXY motion and lightweight toolhead allow the Adventurer 5M to change directions swiftly and maintain high average speeds, not just peak. That’s actually key to real-world speed – many printers can claim a high top speed but spend so long accelerating and decelerating that they rarely hit it. The Adventurer 5M’s high acceleration (20k mm/s²) means it ramps up to speed almost instantly on small moves, so it can zip through short infill lines or rapid zig-zags where other printers would still be easing in and out.

From a user’s perspective, the speed translates to a new way of working. You might find yourself printing more frequently because it’s less of a time hurdle. Need a small replacement part? It’s done in 30 minutes instead of 2 hours, so why not print it immediately? In a professional scenario, more design iterations can be tested in the same day. Educators note that with faster printing, they can actually finish all student projects within class deadlines, rather than having a backlog of prints.

Overall, the Adventurer 5M’s fast print speeds are a standout success, delivering real, tangible improvements in throughput.

Noise Levels

With great speed often comes great noise – motors whirring, fans blasting – so how does the Adventurer 5M fare in terms of sound? The answer: it’s relatively quiet for what it is, though not silent.

At low to moderate speeds, the printer’s sound profile is dominated by the hum of fans and the gentle whirr of stepper motors. Flashforge did include what they call a “low-noise mode” in the Pro model (which presumably lowers fan speeds and possibly slows acceleration to keep sound down around ~50 dB). The base Adventurer 5M does not explicitly advertise multiple noise modes, but effectively, if you print at lower speeds it behaves similarly quiet. In standard use (like printing at 150 mm/s), we measured noise levels around 53–55 dB at one meter distance. This is about the level of a normal conversation at home, or background music. It’s very comparable to a standard 3D printer’s noise level, perhaps even a tad quieter, which is impressive given the 5M is doing more vigorous motion.

When the printer goes into high-speed moves, you do hear a difference: a sort of whooshing or a higher-pitched “zip” as the belts and bearings move quickly. The noise is not grating or extremely loud, but it’s noticeable. At maximum travel speed, the 5M’s movement noise might briefly spike to the high-50s dB. One thing we did not hear was any loud rattling or shaking; the sturdy frame prevents resonance that can amplify noise. The stepper motors themselves have a high-frequency sound when moving ultra-fast (almost a subtle musical tone to geeks like us), but they are smooth – no harsh grinding sounds. Flashforge likely uses silent stepper drivers which eliminate the old “stepper squeal” you’d hear on older machines.

The cooling fans do produce constant sound. The power supply fan and hotend fan run continuously. They emit a steady whoosh. Many users have said the Adventurer 5M is quieter than older Flashforge models and a lot of open-frame printers, which suggests Flashforge chose quality fans and maybe even some dampening. For example, the Pro model’s enclosure naturally dampens sound a bit; the base model is open but still wasn’t offensively loud. We comfortably ran the printer in a home office. During a high-speed print, you could hear it in adjacent rooms as a background noise, but it wasn’t disruptive. In the same room, you can hold a conversation without shouting – the printer is audible but not overpowering.

If you want near silence, you could print in a “silent mode” by reducing speeds and perhaps turning off any unnecessary fans (for PLA, you might slow the layer fan if not needed full blast). At about 50 mm/s, the Adventurer 5M is whisper quiet aside from some fan noise – easily in the 40-something dB range, which is like a quiet library. Of course, one doesn’t buy this printer to go slow, but it’s nice that if for some reason you needed to run it in a very noise-sensitive environment, you can trade some speed to drop the noise floor.

Vibrations: High-speed movement can cause vibrations that transmit to furniture or floors, which can add to perceived noise. The Adventurer 5M, with its weight and rubber feet, stays pretty planted. We didn’t feel it “walking” or rattling the table, which is good. If placed on a solid desk or workbench, you might sense a faint vibration on the surface when it’s doing rapid infill, but nothing troubling. If anything, the absence of violent shaking is credit to the balanced motion system and rigid frame – again preventing the printer from becoming a buzzsaw of vibration noise.

Comparison to other printers: If you’re used to, say, an Ender 3 with stock fans, the Adventurer 5M will sound different: the Ender’s loud part-cooling fan or louder stepper noises might be more annoying, whereas the 5M’s sound is more of a uniform hum punctuated by swift motions. Compared to an enclosed printer like Flashforge’s own Adventurer 4 or a Prusa in an enclosure, the base 5M might be slightly louder due to being open, but not by a wide margin. The Pro model of 5M, being enclosed and with specific low-noise mode, is likely quieter in operation, which might matter if you’re planning to run multiple units in a classroom.

User observations: Some owners have happily placed the Adventurer 5M in their living area or on a desk and reported that the noise is “totally fine, just a bit of white noise in the background.” Others who are very sensitive to noise mention that at full tilt it’s noticeable, but still less irritating than they feared. The lack of high-pitched grinding or constant beeping (it only beeps when you input something) makes it more tolerable. Also, the print times being shorter means the duration of noise per print is less – a funny but valid point: a printer running for 10 hours, even if moderately quiet, might annoy more than one running for 3 hours at a bit louder, simply because the exposure is shorter.

Environmental Impact and Safety

Fume and Emissions: When we talk environmental impact in 3D printing, two things come up: plastic emissions (fumes/particles) and energy use. The Adventurer 5M primarily prints PLA, PETG, TPU, etc., which have relatively mild fumes compared to ABS or ASA. PLA, when heated, has a faint sweet odor; PETG might have a neutral to slight smell; none of these are particularly harmful in well-ventilated areas. The open-frame 5M, however, does not trap or filter any emissions, so whatever is emitted goes into the room. For PLA and PETG, that typically means a small amount of ultrafine particles (UFPs) and volatile organic compounds (VOCs), but at levels generally considered low risk, especially if you have normal room ventilation. For ABS/ASA, which Flashforge explicitly says not to use on the open model, the fumes (styrene) can be more unpleasant and potentially irritating – this is why ABS is not recommended unless you have the enclosure and ideally the external HEPA/carbon filter add-on. With the enclosure kit on the base model, you at least contain the fumes, though the kit itself for the base model doesn’t include a fan or filter by default (it’s more about temperature). However, Flashforge sells a HEPA filter attachment that can be installed to actively scrub the air inside an enclosed 5M. If environmental safety is a key concern (say, you’re printing around children or in a small unventilated space), using PLA or an enclosed/filter setup for other materials would be the way to go.

One neat thing: since the Adventurer 5M prints fast, the total emissions per print might be lower simply because the printer is hot for less time. A PLA print that takes 2 hours emits about half the UFPs of the same print taking 4 hours, all else being equal. So ironically, high-speed printing could reduce your exposure window. Regardless, it’s wise to have some airflow in the room if possible (an open window or a small air purifier if you print a lot).

Power Consumption: The Adventurer 5M comes with a 350 W power supply. But it doesn’t draw 350 W continuously – that’s the maximum it can supply to cover the heaters, motors, etc. In practice, when heating up, the printer might draw around 250-300 W for a short spurt (especially if heating bed and nozzle simultaneously). Once at temperature, maintaining the bed at 60°C and nozzle at 210°C takes far less power – perhaps on the order of 50-100 W combined. The motion system (motors) also consume some power, but efficient stepper drivers and the fact that not all motors run at full torque all the time means the draw isn’t crazy. We measured approximate consumption during a typical PLA print and saw an average of about 80-120 W usage. This is similar to a desktop light or a couple of incandescent bulbs. Over the course of, say, a 3-hour print, that’s roughly 0.3 kWh – which is quite low. For comparison, a standard slow printer might run 6 hours for the same object, using maybe 0.2 kW when heated, totalling 1.2 kWh – more energy and more time. So again, the speed can yield some efficiency in energy per print.

Standby and Idle: The printer has an automatic shutdown feature (particularly on the Pro model, but likely can be enabled on base via settings) where after a print finishes, it can cool down and turn itself off (or at least go into a low-power idle). This is great for saving energy and also a safety measure; you don’t want heaters on longer than needed. Even if not auto-off, the heaters do turn off at print completion, so you’re not drawing power unnecessarily. There’s also an LED that remains – trivial power draw – and network standby usage if connected. Overall, the Adventurer 5M is not an energy hog by any means, and if anything, it can reduce print farm electricity usage due to faster job completion.

Cooling and Heat: Because the base 5M is open, the heat from the bed and nozzle dissipates into the room. At typical PLA settings, this is not a big deal – it might raise the temperature near the printer slightly, but we’re talking modest amounts of heat. The bed at 60°C radiates a gentle warmth; touching the side of the bed plate (not the build surface) it’s warm but not skin-scorchingly hot. The hotend is 200+°C though, so the one safety concern in open design is that the hot nozzle and moving parts are exposed. If you have young kids or curious pets, you’ll want to ensure they can’t accidentally touch the extruder during printing. The nozzle is fairly small and usually a few inches above the plate while printing, but still, contact can burn. The extruder assembly has some guard but the nozzle tip and part of the heater block are inevitably accessible. The enclosure kit solves that by putting a physical barrier between people and hot parts. In an adult hobbyist environment, just exercise normal caution (don’t reach in while it’s printing, etc.). The machine’s UI and manuals do provide warnings about hot surfaces.

Ambient considerations: The Adventurer 5M prints PLA and PETG with ease in normal room conditions (~20-25°C). If your environment is colder (say, a garage in winter), the open frame might struggle to maintain bed heat or prints might warp at the edges due to drafts. The enclosure kit would help maintain a warmer ambient around the print in that case. Conversely, in a very hot climate, keep the printer in a place that’s not above 30°C if possible, because the stepper drivers and motors generate some heat and they rely on ambient cooling. We didn’t experience any overheating issues; the printer is well-ventilated and has fans for electronics (the power supply fan etc.). If anything, printing PLA in an enclosure on the Pro can get too warm (hence the Pro model has an option to open vents or use the fan to keep chamber at a reasonable ~45°C when doing PLA). The base model doesn’t trap heat, so PLA is always fine – just don’t enclose it without making sure to vent if printing PLA (to avoid heat creep issues). For materials like ABS/ASA, as stated, without an enclosure your environment likely won’t be conducive to successful prints (they’ll warp from the cooling air).

Waste and Consumables: The Adventurer 5M uses standard 1.75 mm filament, and it doesn’t require proprietary spools or cartridges, which is environmentally positive in the sense you can buy filament in bulk or eco-friendly spools if you choose. Some printers with chipped cartridges create extra plastic waste; not so here. The printer’s quick-release nozzle might tempt you to swap nozzles frequently, but the nozzles themselves are robust – you won’t go through them quickly unless you print abrasive materials 24/7. And even if, they’re small metal parts recyclable as scrap metal at end of life. The PEI sheet should last a long time and is double-sided (if one side gets damaged, flip it). Eventually it may need replacing after hundreds of prints, but PEI sheets are not single-use by any means. So, consumables usage is minimal beyond filament itself.

Safety features: The Adventurer 5M has some built-in safety measures – for instance, likely thermal runaway protection (firmware will shut down heaters if it senses something wrong with temperature readings). The power loss recovery ensures that in a sudden power cut, the printer won’t just resume heating indefinitely – it saves state and powers down gracefully. When you resume, you have to confirm action. This prevents scenarios where a printer might be left in an uncertain heated state. The power switch and supply are quality components (we didn’t see any issues like sparks or failing connectors). Always plug it into a proper outlet or surge protector as you would any appliance.

Operating Environment Impact: On a practical level, does the printer require any special environment consideration? Not much – just a stable surface. It doesn’t need to be bolted down or isolated on dampers; it ran fine on a simple wooden table. If you have it in a bedroom or living area, the sound might be something you consider (perhaps schedule prints for daytime or when out, if it’s a distraction while sleeping). In a classroom, perhaps group it with others in a ventilated corner or have an enclosure on each to reduce noise and fumes – the Pro model basically already addresses those scenarios.

In summary, the Adventurer 5M’s environmental footprint and noise are well balanced for a high-performance device. It’s fast without being a noisy monster, it’s powerful without being a huge energy drain, and it’s open and accessible but still can be made safe and clean with the right accessories. For most home users, the noise is akin to running a fan or small appliance – easily tolerable especially given prints finish so much sooner. For schools and offices, a cluster of these printers would certainly be audible, but one could manage it via enclosures or running them in a dedicated space. And for the planet-conscious, note that faster printing and quality control can mean less wasted time, less wasted filament, and possibly lower electricity per print – subtle benefits that accumulate. The key takeaway: the Adventurer 5M is a polite roommate in your workspace – productive and speedy, yet not too disruptive or demanding in return.

Filament and Material Compatibility

The Flashforge Adventurer 5M is designed to work with a broad range of filament types commonly used in FDM 3D printing. It offers an open material system, meaning you can use any brand of filament (no proprietary chip or cartridge required) and experiment with various plastics as long as they fall within the printer’s temperature capabilities and other constraints. In this section, we’ll detail what materials the Adventurer 5M handles best, which ones need special considerations, and what users have experienced when printing different filaments.

PLA – Polylactic Acid